The Essential Guide to Choosing the Right Wooden Packaging for Your Business

Choosing the right wooden packaging ensures safe, efficient transport of goods. Key factors include product size, weight, and fragility, transportation method, and customization needs for protection and branding. Opt for FSC-certified, sustainable options to reduce environmental impact. Balancing quality and budget with a trusted supplier is essential for meeting business goals.

Sustainable Packaging Options: Why Wooden Pallets Are the Eco-Friendly Choice

Wooden pallets are an eco-friendly packaging option due to their renewable nature, biodegradability, and lower manufacturing impact. Made from timber, they decompose naturally and require less energy to produce than plastic or metal. Their durability allows for multiple uses, and damaged pallets can often be repaired. At their end of life, they can be recycled into wood chips, mulch, or biofuel, minimizing waste. To maximize benefits, source pallets from certified suppliers to support responsible forestry. Choosing wooden pallets helps businesses reduce their ecological footprint and promote sustainability.

The Best Animal Carriers for Safe Transport and Export

Ensuring the safety and comfort of animals during transport is crucial, whether for breeding, export, or relocation. Selecting the appropriate carrier depends on the animal's size, species, and journey requirements. Common options include wooden crates for larger animals, plastic carriers for small to medium-sized pets, and wire mesh cages for enhanced ventilation. Custom-designed carriers offer tailored solutions to meet specific needs, ensuring compliance with export standards and regulations. Key considerations when choosing a carrier include adequate ventilation, secure locking mechanisms, and sufficient space for the animal to move comfortably. Properly designed carriers not only protect animals from harm but also reduce stress during transit, facilitating a safer and more humane transportation process.

Custom Pallets vs. Standard Pallets: What’s the Difference?

Choosing between custom and standard pallets is crucial for efficient shipping and storage. Standard pallets are cost-effective, readily available, and adhere to international sizing, ensuring compatibility across various industries. However, they may not meet specific requirements for unique product dimensions, heavy loads, or industry-specific standards. Custom pallets offer tailored solutions for irregularly shaped products, enhanced protection for fragile items, and can incorporate branding elements. While more expensive, they provide the necessary support and compliance for specialized needs. Selecting the appropriate pallet type depends on factors such as product characteristics, shipping volume, budget, and logistical considerations.

The Benefits of FSC-Certified Timber in Industrial Packaging

FSC (Forest Stewardship Council) certification ensures that wood products come from responsibly managed forests that provide environmental, social, and economic benefits. It promotes sustainable practices, protects biodiversity, and upholds the rights of workers and local communities. Choosing FSC-certified products supports ethical sourcing and helps combat deforestation, making it a vital step toward environmental conservation and sustainability.

How to Choose the Right Type of Standard Pallet for Your Business

Selecting the right pallet is important for safe and efficient storage and transport. Consider key factors like load capacity, board spacing, entry style (two-way or four-way), and design options like winged or reversible pallets. Use local pallets for domestic purposes and kiln-dried export pallets for international shipping that follows ISPM 15 standards. Choose based on your business needs.

What is the standard size for wooden pallets?

A brief overview of the standard pallet dimensions utilized for intercontinental shipping is essential for understanding their widespread application across various regions. These dimensions typically adhere to specific guidelines to ensure compatibility with shipping containers and transport equipment. Continue reading for more information.

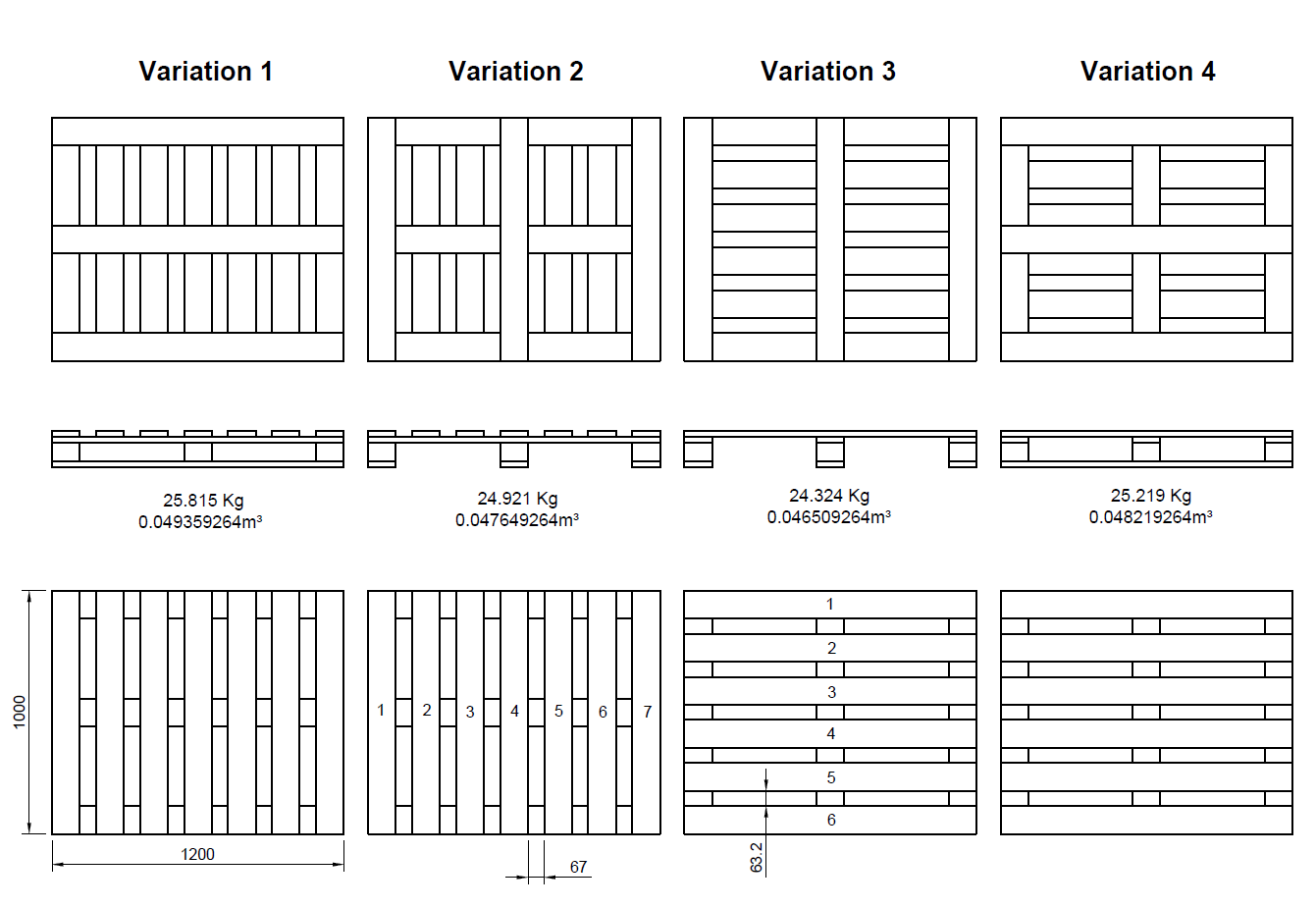

Wooden pallet: Most efficient board orientation.

An in-depth analysis of how the specific orientation of the deckboards of a wooden pallet can significantly influence both the weight and the overall cost of manufacturing the pallet will be presented. This examination will consider various factors, specifically material efficiency related to different arrangements of the deckboards.