Wooden pallet: Most efficient board orientation.

Introduction:

For this article we will compare how the board orientations influence the weight and cost of rectangular wooden pallets. For the sake of this analysis we will use a uniform dimension of wood for the deck (114x25mm) and attempt to retain similar spacing between deckboards.

Terminology and Assumptions:

2 way entry pallet - Also known as Stringer pallets. These pallets offer forklift access from 2 sides.

4 way entry pallet - Also known as Block pallets. These pallets offer forklift access from all 4 sides.

Deckboard - Top planks of the pallet

Stringers - Support beam/plank

Runners - Bottom planks of the pallet

Width (for the sake of this article) = 1000mm

Length (for the sake of this article) = 1200mm

Wooden pallet volume is calucalted with the following formula: Each plank = Length (mm) x Width (mm) x Thickness (mm) = Cubic Meter (m3) per plank x quantity of planks.

Cost per pallet is calculated by the following formula: m3 x Price/m3

For this article we will asume the weight/density of Kiln dried SA Pine is 523kg/m3 and the price per cube of lumber is R2500/m3 (South African Rand/ZAR).

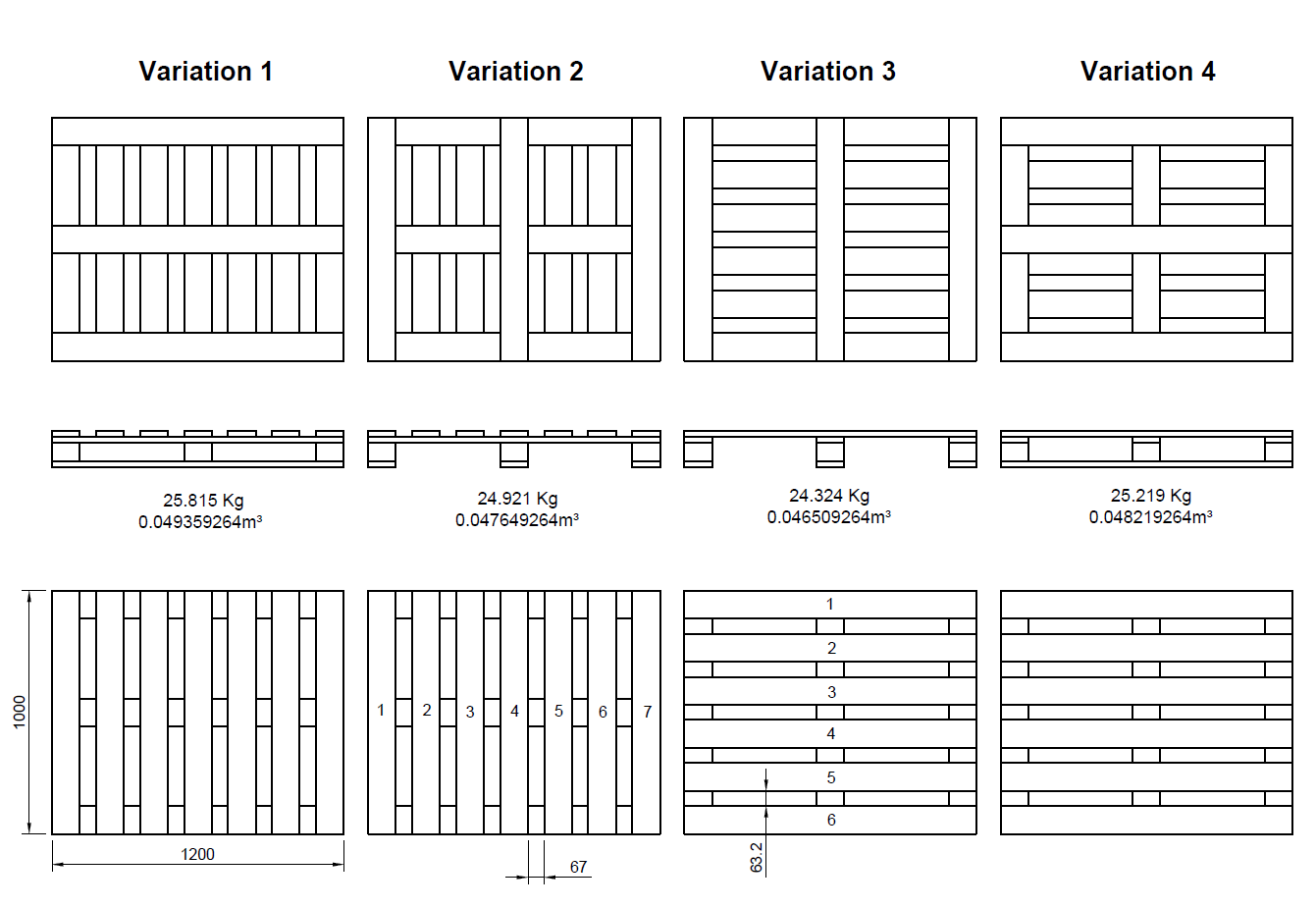

4 way entry wooden pallet:

We have made 4 variations; 1st group of two: the deck boards are equal to the width of 1000mm. 2nd group of two: the deckboards are equal to the length of 1200mm. Within each group we alternated the runners accordingly. (4 Way pallet stringers need to be perpendicular to the deckboards, limiting us to only alternate the runners).

Variation 1: 7 Deckboards with 67mm spacing

Deckboards = 1000mm

Stringers = 1200mm

Runners = 1200mm

Variation 2: 7 Deckboards with 67mm spacing

Deckboards = 1000mm

Stringers = 1200mm

Runners = 1000mm

Variation 3: 6 Deckboards with 63.2mm spacing

Deckboards = 1200mm

Stringers = 1000mm

Runners = 1000mm

Variation 4: 6 Deckboards with 63.2mm spacing

Deckboards = 1200mm

Stringers = 1000mm

Runners = 1200mm

Results:

Variation 1:

Estimated Weight of 25.815 Kg & Volume of 0.049359264m3

Cost of wood: R123.40

Variation 2:

Estimated Weight of 24.921 Kg & Volume of 0.047649264m3

Cost of wood: R119.12

Variation 3:

Estimated Weight of 24.324 Kg & Volume of 0.046509264m3

Cost of wood: R116.27

Variation 4:

Estimated Weight of 25.219 Kg & Volume of 0.048219264m3

Cost of wood: R120.55

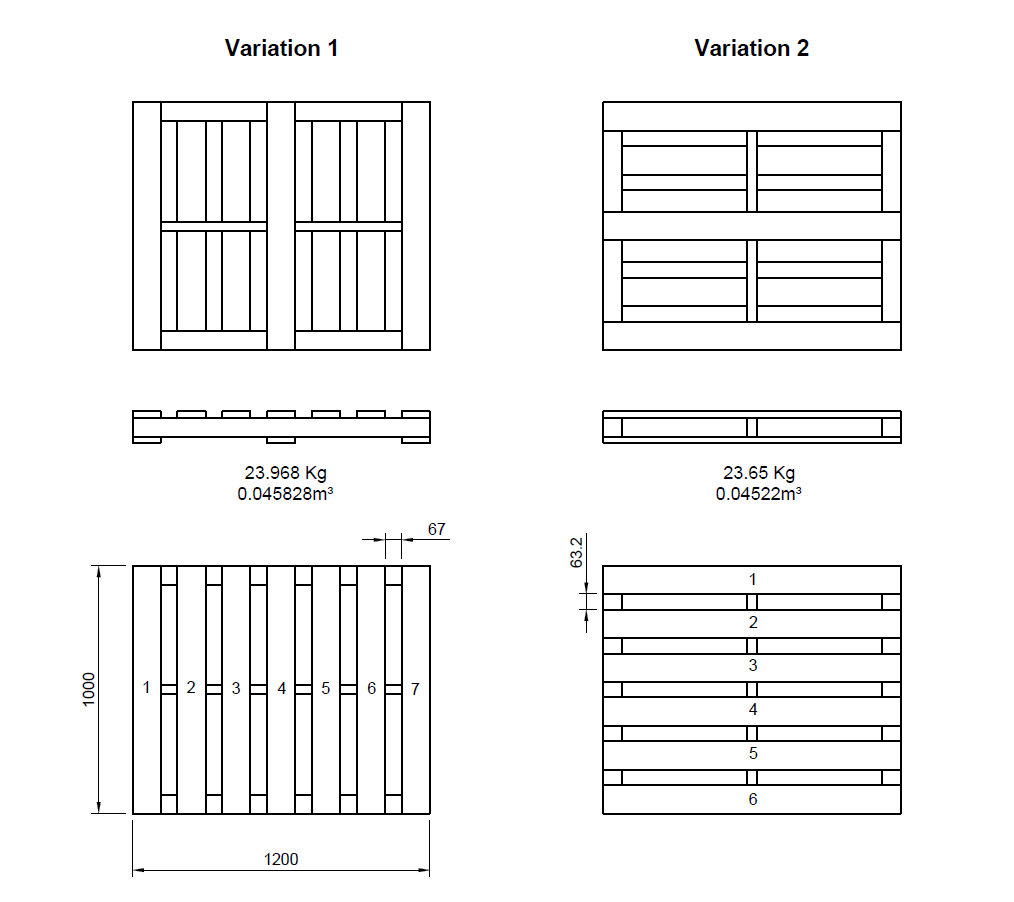

2 way entry wooden pallet:

We have made 2 variations; 1st, the deck boards are equal to the width of 1000mm. 2nd, the deckboards are equal to the length of 1200mm.

Variation 1: 7 Deckboards with 67mm spacing

Deckboards = 1000mm

Stringers = 1200mm

Runners = 1000mm

Variation 2: 6 Deckboards with 63.2mm spacing

Deckboards = 1200mm

Stringers = 1000mm

Runners = 1200mm

Results:

Variation 1:

Estimated Weight of 23.968 Kg & Volume of 0.045828m3

Cost of wood: R114.57

Variation 2:

Estimated Weight of 23.65 Kg & Volume of 0.04522m3

Cost of wood: R113.05

Conclusion:

It would appear that the most cost effective 4 way entry wooden pallet would be variation 3. It is also the easier construction variation with the stringers and blocks being manufactured individually, allowing for a more efficient production line assembling of the pallets. Variation 3 is the most cost effective wooden pallet with the 2nd being R2.85 more expensive. Variation 3 is also the lightest with the 2nd coming in at an additional 0.597 Kg.

It would appear that the most cost effective 2 way entry wooden pallet would be variation 2. However, the difference between the 2 variations are near negligible.

Factors to consider:

When choosing a wooden pallet type or construction variation. Keep in mind how the pallet will be used. Some of these variations mentioned within this article will be less suited for pallet rack systems where the wooden pallet is placed on load bearing beams. The more planks spanning the gap between these beams the better the pallet will perform in the long term.